Lubricant Systems, Storage, and Handling

It’s not enough to have the right lubricant. Keep your facility up and running with proper lubricant storage and handling.

Lubrication Systems Company combined with RelaDyne Reliability Services packages industry knowledge and experience with equipment design and manufacturing to meet your lubrication needs, standard or custom. We routinely customize equipment and skids for our customers.

Our products are used around the world with the most common products being:

Pre-Engineered Lube Oil Skids

Lube oil skids with limited options ready for quick construction and installation.

Custom Lube Oil Skids

Turn-key API 614 or non-API lube oil skids. Can be designed and fabricated to meet any customer specifications and operating conditions.

Bulk Tanks

Base-mounted bulk tanks for fluid storage and external capacity increases.

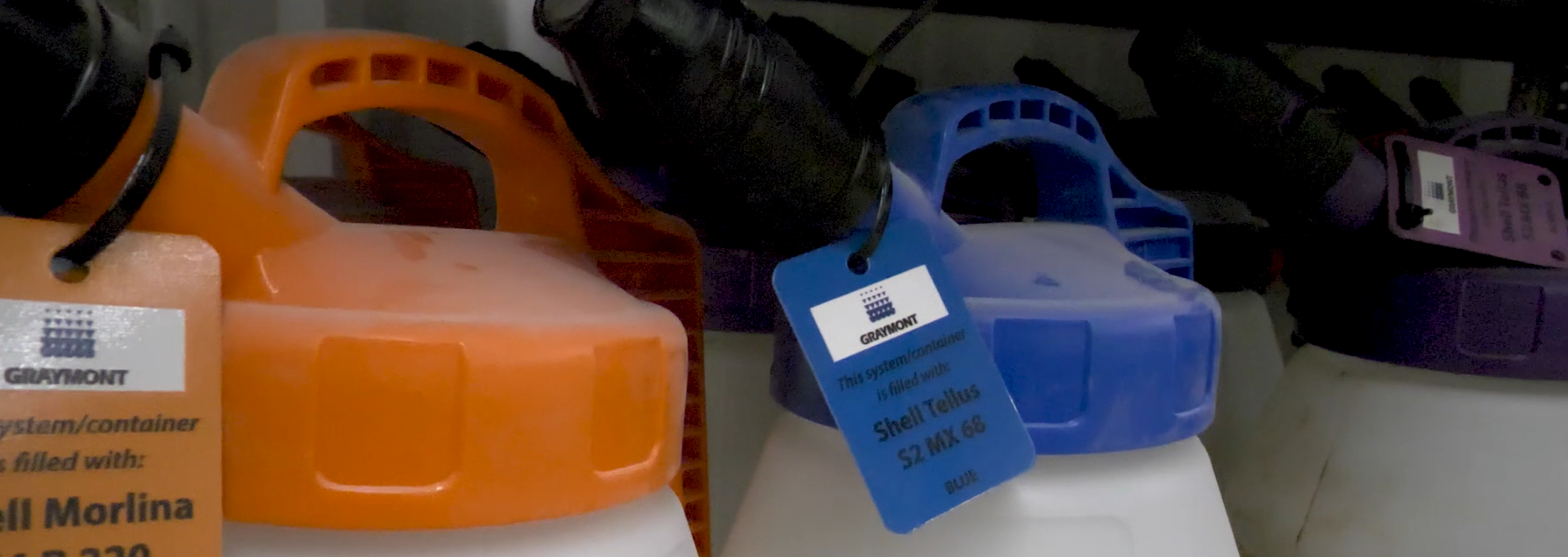

Lube Room and Components

Fluids management requires proper storage and handling. Our lube rooms and components deliver easy to manage processes and equipment to ensure you have clean, reliable lubricants at all times.

Diesel Exhaust Fluid (DEF) Equipment

As your DEF trusted advisor, RelaDyne can support your growing requirement for Diesel Exhaust Fluid with our API-certified product and closed-loop equipment handling solutions.

RelaDyne supplies customers with industry-leading Diesel Exhaust Fluid (DEF) solutions across the central corridor of the US. Our world-class manufacturing partners give us the ability to provide our customers with the highest standard in diesel exhaust fluid supply and service in the industry today.

Custom Component Fabrication

RelaDyne Reliability Services offers custom-fabricated wire screen flushing fixtures and oil flushing spools for your oil flush needs. Contact us to discuss your requirements for your upcoming projects.

Example components include:

- Wire screen baskets

- Screen targets

- Pipe spool pieces

- Pipe manifolds