Varnish Mitigation

RelaDyne’s patented Varnish Mitigation solution is engineered to combat the industry’s widespread varnish issue. This specialized, kidney-loop processing technology removes varnish from your oil, strips it from valves and interiors of your equipment, and helps prevent it from coming back.

What is Varnish?

Varnish is the buildup of deposits (formed as oil degrades) that stick to the internal workings of lubricating and hydraulic oil systems. Due to the ever-increasing strain placed on equipment and the industry’s trend towards primarily Group II base oils, varnish has become a major issue throughout the industrial world.

RelaDyne's Patented Process

RelaDyne has developed a patented kidney-loop oil processing technology to remove harmful varnish from lubrication systems. The process has been uniquely developed to remove lubricating oil varnish and system varnish without downtime or loss of production. This proprietary process attacks varnish at its source and lets our customers continue to operate without missing a beat.

Industry Applications

- Power generation (traditional and wind turbines)

- Hydraulic systems

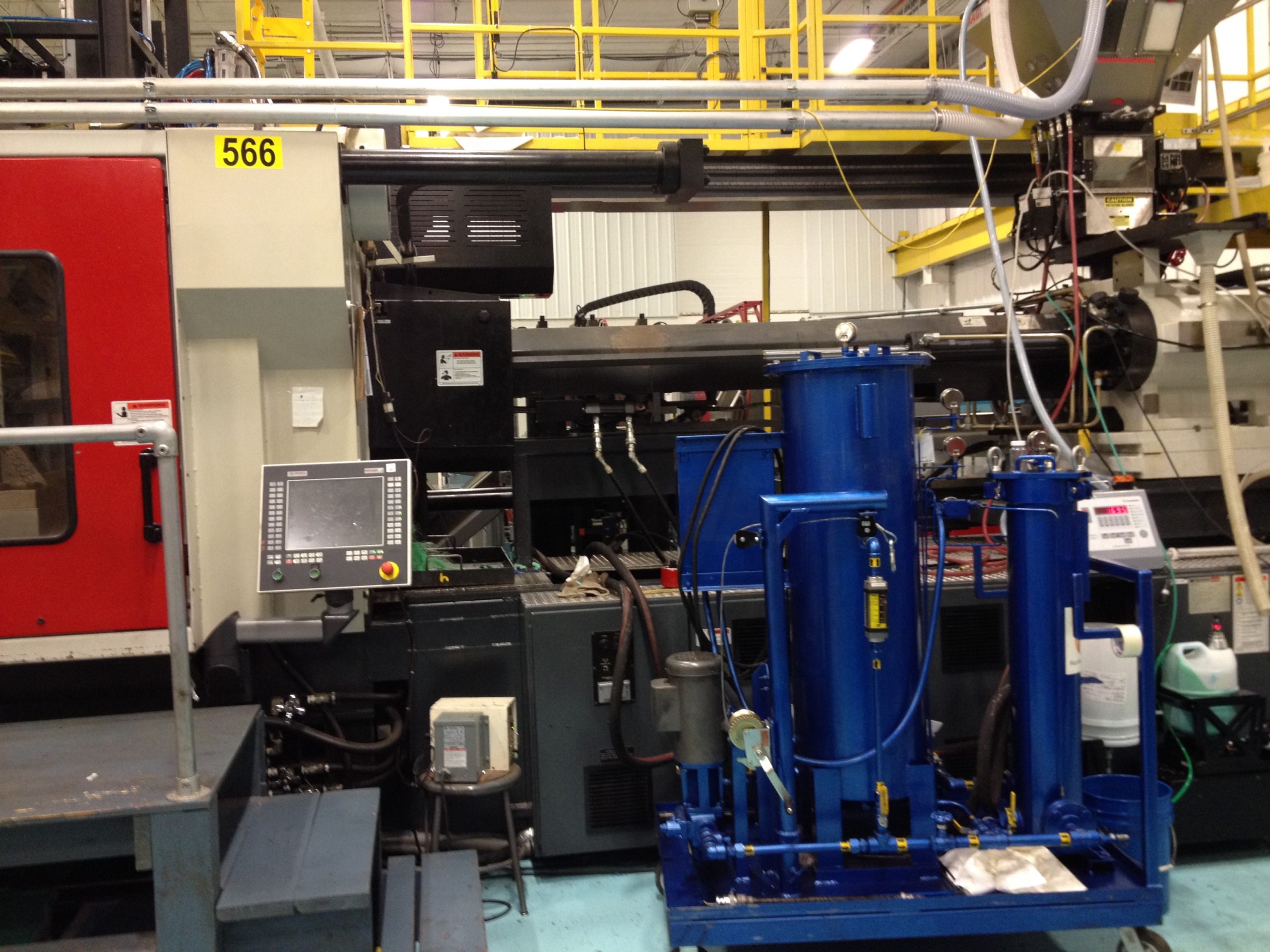

- Plastic injection hydraulics

- Metal stamping/forging hydraulic systems

- Combustion turbine lubricating systems

- Compressor lubrication systems

Reach out today to discuss your specific needs and how we can help you with varnish challenges you may be experiencing.

Looking for a one-stop shop for your industrial products and services? We have you covered. See the complete RelaDyne RelaTECH portfolio of products.