Along with tar and sludge, varnish is one of the results of oxidation, a chemical process created from the friction and heat of operating a lubricating oil or hydraulic machine. This friction and heat cause the quality of a machine’s lubricating oil to deteriorate over time. Once degradation occurs, byproducts from the oil start to settle throughout the system. Over time, these byproducts will attach to the surfaces of the equipment, creating a sticky coating called varnish.

The presence of varnish also attracts other contaminants, forming an abrasive surface on piping, valves, filters and other components that are vital to the performance of your equipment.

Equipment Problems Caused by Varnish

Varnish forms after oxidation and the development of free radicals. These sticky deposits attach to the metal surfaces of strainers, piping, valves, filters, and other equipment. As a result, these sticky deposits and other small particles continue to build up around and can form a rough and dangerous surface.

Here are a few other equipment problems caused by varnish:

- Sticking movable parts such as directional valves

- Increased wear due to varnish attracting dirt and solid contaminants

- A reduction in filter efficiency and filter plugging

- Increased maintenance costs due to cleanup and removal of oil

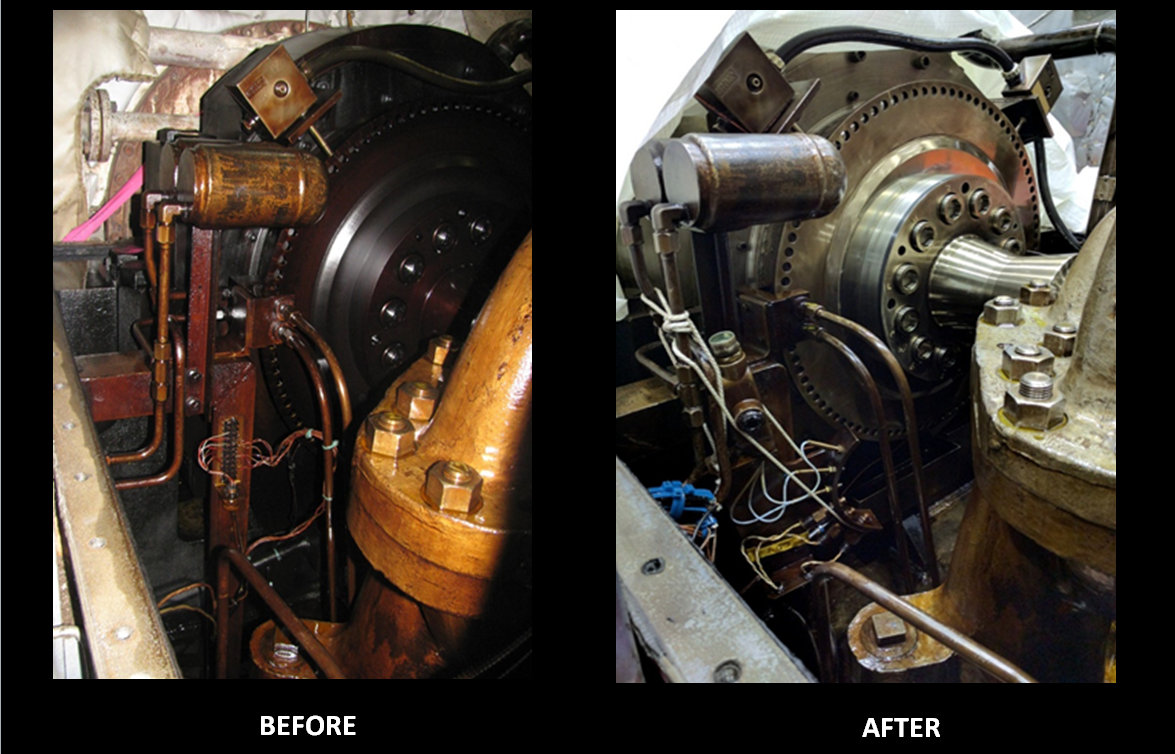

Preventing and Resolving Varnish Problems

Recent advances in hydraulic control and lubricating oil systems help reduce many varnish problems. Cleaning methods such as mechanical filters and detergents show mixed results. Oil analysis tests are unreliable in determining a machine’s potential varnish levels.

At RelaDyne, we offer a patented oil processing technology to remove harmful varnish from lubrication systems. This technology removes varnish from circulating oil and strips it away from valves and the interiors of your equipment. If you are looking for long-term solutions for varnish that sneaks up on your equipment, contact us today.