As the market for more fuel efficient cars continues to increase, the latest and greatest technology of Gasoline Direct Injection (GDI) engines are gradually becoming a standard engine choice for Original Equipment Manufacturers (OEMs). As GDI engines become more and more popular, the previously common Port Fuel Injection engines are slowly losing their momentum and experts suspect that nearly 39 percent of all passenger vehicles will be manufactured using a GDI engine by the year 2020.

How GDI Engines Work

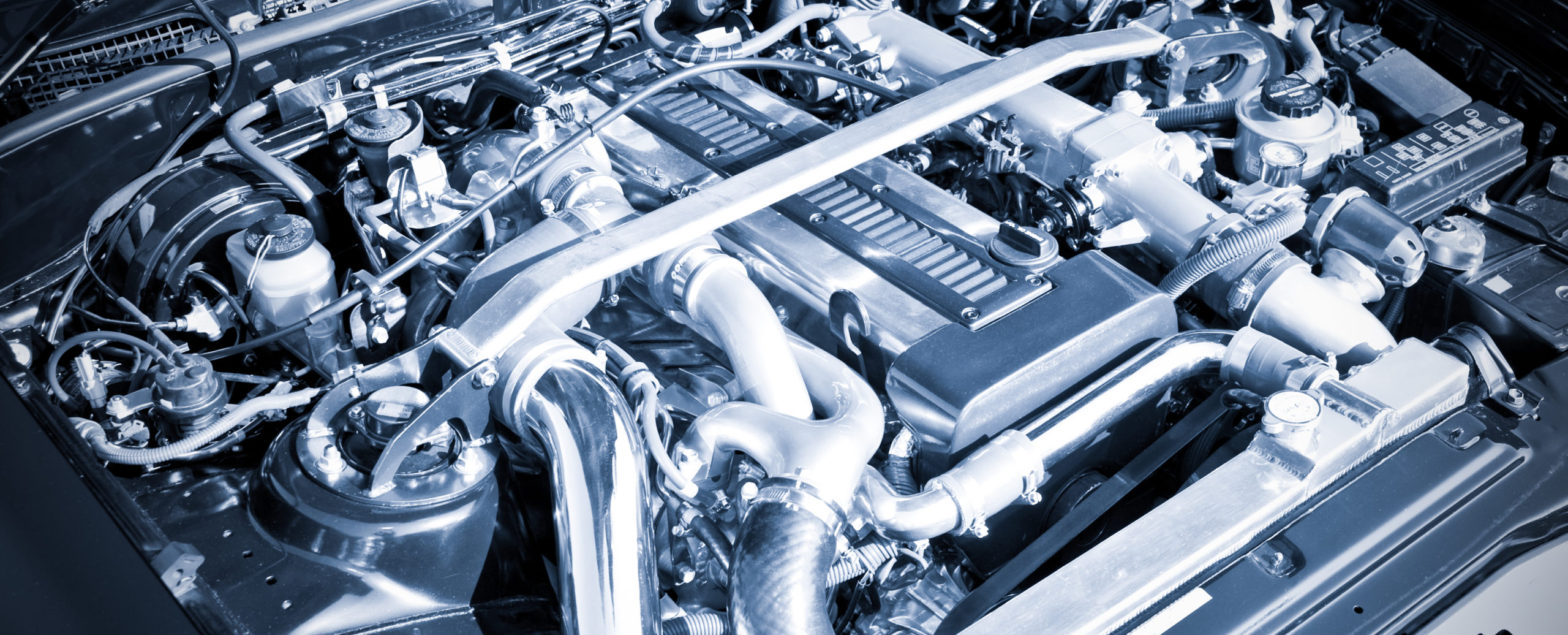

The GDI engine’s fuel efficiency comes from the fact that it is a smaller engine. To accomplish the power equivalency of larger PFI engines, GDI engines operate by spraying fuel directly into the engine cylinder, providing a cooling effect. This allows the engine to produce higher compression ratios and higher torque, directly resulting in greater fuel efficiency. This process is also similar in Turbocharged Gasoline Direct Injection (TGDI) engines, making their servicing needs the same.

The power a GDI engine packs for its size creates a more extreme environment where a delicate balance of durability and protection from lubricants is essential to its health and life cycle.

What does this mean for Quick Lubes and GDI engine vehicle owners?

So what does this mean for you as an automotive installer or consumer? Our service habits for GDI engine vehicles must differ from that of PFI engines in order to meet the needs of this small, more powerful and consequently higher maintenance engine.

While the maintenance needs require more time and energy, the performance and fuel efficiency of the GDI engines make the extra care worth it. Failing to provide adequate care can be devastating to the engine life and overall vehicle performance.

The Risks of Inadequate Care of GDI Engines

By not taking OEM recommendations seriously when providing care for GDI engines, you can single-handedly set these vehicles on a fast track for many operational and performance issues, such as:

Catastrophic knock damage caused by Low Speed Pre-Ignition (LSPI)

Accelerated Timing Chain Wear

Turbo deposits and oil oxidation that cause engine failure

Higher wear rates due to greater loads on critical components

Severe running conditions leading to faster rates of oxidation

To meet these new maintenance needs, RelaDyne has leveraged DuraMAX oils with Wynn’s Preventative and Maintenance products to create a 3-step solution to caring for GDI engines.

The 3-Step Solution

1. Oil System Cleaner

Oil System Cleaner successfully dissolves and suspends engine oil deposits throughout engine and provides lubrication and extra wear protection during cleaning process.

2. DuraMAX Full Synthetic dexos1® Gen 2 Motor Oils

These premium full synthetic motor oils are the best protection for your GDI & TGDI engines, ensuring superior performance and an optimal life cycle.

3. Fuel System Cleaner

Fuel System Cleaner is especially important for ethanol and fuel-injected engines which tend to build harmful deposits more easily. Powerful detergents and solvents in fuel system cleaners dissolve fuel and carbon deposits found on the fuel-injectors, intake valves, carburetor, and combustion chambers.

With the knowledge of this 3-step solution and the dependability of DuraMAX oils and the oil and fuel system cleaners, you will greatly increase GDI engine life and performance potential!

For more information on this 3-step solution and how you can work with us to provide better servicing for GDI & TGDI engines, contact Bob Johnson, 317-696-3009.