Full-service equipment design, build, and customization to meet the demands of our end-user, EPC (Engineering, Procurement, and Construction) and OEM customers.

Specialty experience delivering Ex-rated (hazardous area) equipment meeting all industry and regional specifications. Certifications include ATEX, CSA, EAC, GOST, IEC, INMETRO, KOSHA, NEC, NEMA, PESO, and UL.

LubriMist® Oil Mist Lubrication Generators & Systems

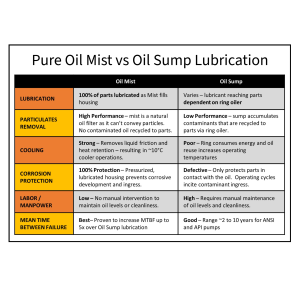

LubriMist® Oil Mist Lubrication Systems offer you the best of two worlds – fast return on investment and a greener‚ cleaner facility.

As the industry leader, LSC has delivered over 5‚000 LubriMist® Oil Mist generators and systems around the globe. Oil Mist lubrication has proven the most reliable lubrication option across many industries, from heavy farm equipment to arctic refineries.

LubriMist® systems deliver continuous service with no operator intervention. These efficient‚ centralized lubrication systems use compressed air to produce a clean mixture of low-pressure‚ atomized lubrication oil in precise amounts to ensure the integrity of rotating equipment.

Available in a variety of sizes and with a full range of mechanical and electrical features, Oil Mist lubrication meets virtually every lubrication system need. From large-scale‚ fully automated systems lubricating 100+ pieces of equipment in a petrochemical plant to single bearing lubrication on a woodworking machine, there’s a LubriMist® Oil Mist lubrication system to meet your needs.

Oil Mist Generator Models

- VM – 1 gallon, open loop

- VO – 3 gallon, open loop

- LubriMate (LM) – 1 gallon, closed loop

- CVT – Redundant systems, open/closed loop

- CHB – Redundant systems, open/closed loop

- IVT – Redundant systems, all-weather, integrated bulk tank, open/closed loop

Model: IVT

Model: CVT

Hazardous Area Expertise

LubriMist® oil mist generators are installed in some of the most stringent, hazardous areas in the world. Our equipment includes various 3rd party manufacturing and Ex certifications, including:

- ATEX

- CE

- CSA

- EAC

- GOST

- IECEX

- INMETRO

- NEC

- NEMA

- PESO

- UL

Parts, Accessories, & Service

Contact LSC for system and generator replacement parts, upgrades, and accessories. Parts and upgrades are typically available for out-of-production generators, including: JD, JR, SSV, EXP, VFP, and NV.

Commonly requested accessories include:

- Drain legs

- Collection containers

- Bulk & demisting tanks

- Mist manifolds

- Purge mist vent/fills

- Constant oilers

- Preservation packages

- Mobile oil / fill carts

LSC offers turn-key, on-site equipment services including installation, inspection, start-up / commissioning, maintenance, and repair. All services adhere to OEM specifications and standards.

LSO SureMist Series LubriMist® Synthetic Oil

Ensure world-class equipment reliability with LubriMist® specialty formulated Oil Mist oil. Available in full or partially synthetic blends.

- LSO – Full synthetic, excellent misting and lubrication

- SureMist – Full synthetic, excellent misting and lubrication with 98% stray mist elimination

- LPSO – Partial synthetic, excellent misting and lubrication

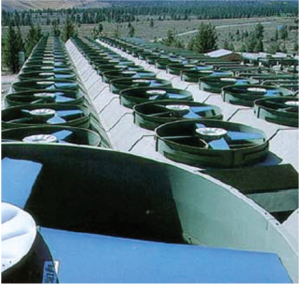

Mistlock™ for Air Cooled Heat Exchangers

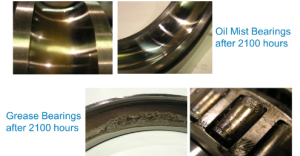

Lubrication Systems Company combined with RelaDyne Reliability Services offers industry-leading bearing reliability for Air Cooled Heat Exchangers (ACHE). ACHE bearings are often sited as some of the most unreliable and difficult to access and maintain bearings in a facility. Our MistLock product enables users to upgrade ACHE lubrication methodology from grease to Oil Mist – typically increasing reliability at least three fold.

How MistLock™ Works

Patented MistLock™ bearings transition 50 years of Oil Mist lubrication best practices from horizontal pumps and motors to your troublesome ACHE bearings. MistLock™ delivers a maintenance free, closed-loop oil mist lubricated bearing that seals oil mist in the bearing frame, thus eliminating any stray mist or coalesced oil.

MistLock™ automates delivery of a clean, cool oil supply that evenly coats all bearing surfaces and reduces operating temperatures up to 10 degrees. The bearing’s seal travels with the bearing inside the conical retainer, allowing for up to 3 degrees of angular or parallel misalignment and typically eliminating shimming.

Built for difficult environment, the MistLock™ bearing is uniquely qualified to deliver reliability in all conditions. The design incorporates bearing support mechanisms that adapt to accommodate axial thermal expansion, typical with environmental and operational temperature swings. The design also maintains a constant positive pressure inside the bearing housing eliminating ingress of environmental contaminants during both operating and stand-by periods.

LSC Mistlock™ Technology

Advanced Wear Testing

Oil & Hydraulic Fluid Purification and Reconditioning

Ensure equipment reliability and eliminate expensive fluid disposal or replacement with RelaDyne Reliability Services’ comprehensive suite of Purification and Reconditioning equipment.

This equipment is available for:

Contact us for equipment parts, upgrades, accessories, and on-site equipment services. Services include installation, inspection, start-up, commissioning, maintenance, repair, and refurbishment. All parts and services adhere to OEM specification and standards.

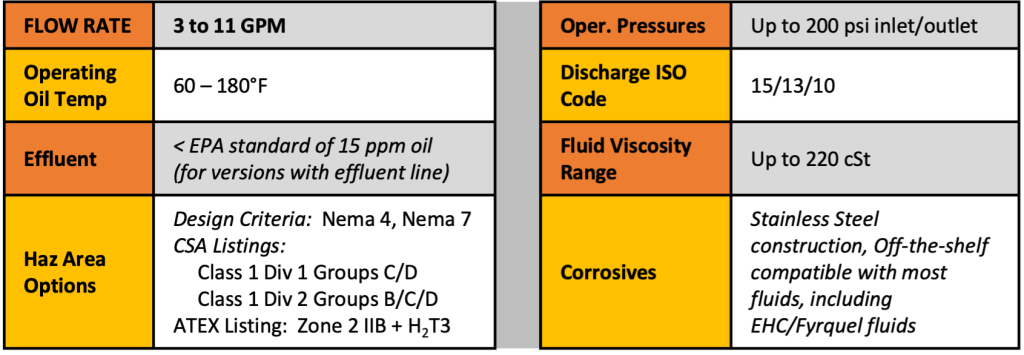

ThermoJet® Oil Purifiers

ThermoJet® delivers industry leading oil dehydration and degasification through Lubrication Systems Company’s patented air-stripping technology. With over 30 years of global industrial expertise ThermoJet® is your trusted, safe, “set-and-forget” solution.

- Removes free, emulsified & dissolved water. Reach levels below 50 ppm!

- Safely remove gases including H2S, ethane, chlorine, and propane

- Discharge to ambient, flare, or a scrubber

- Doesn’t require operational support

- Kidney loop can be in lube oil system or embedded in compressor / turbine lube oil reservoir

- Combine with various media or varnish filtration options (Ion Exchange, Depth Media, SelectSorb, Fuller’s Earth, etc.) to create a full-service system

The ThermoJet® air stripping process combines nitrogen or ambient air stripping with pump-free vacuum principles to safely, quickly and consistently purify oil. This unit sets the industry benchmark for delivering peace-of-mind through years of hassle-free, operator-free functionality.

Key Characteristics and Specifications

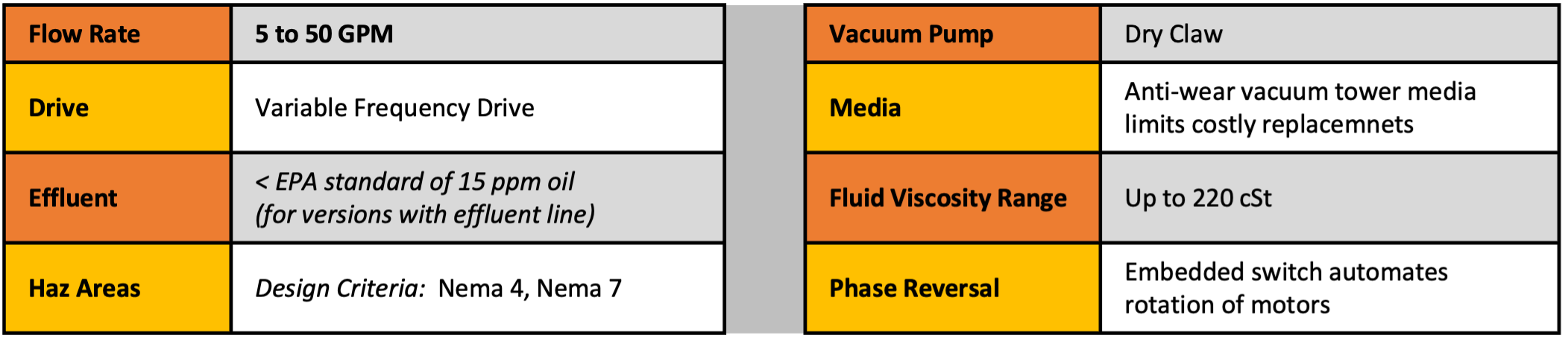

Vacuum Dehydration Units (VDUs)

RelaDyne Reliability Services offers best-in-class Vacuum Dehydrators based on years of design and operational experience.

Remove free, emulsified & dissolved water

Safely remove gasses including H2S, ethane, chlorine, and propane

Discharge to ambient, flare or a scrubber

Kidney loop in lube oil systems

Combine with various media or varnish filtration options to create a full-service system

Self-contained and skid-mounted for increased mobility and ease-of-use

PLC controller for simple operations

Water and gas contamination can cause extreme damage to bearings and hydraulics as well as become a safety concern when hydrocarbons are saturated in the oil. Up to 75% of mechanical failure can be attributed to particulate or water contamination in oil. Preventing contaminants from getting in the oil allows the oil to operate effectively and increases the overall reliability of your equipment.

Key Characteristics and Specifications

General Filtration

The constant in proper lubrication management is product cleanliness. RelaDyne Reliability Services provides the products you need to support filtration from lubricant reception to initial equipment fill to lubricant replacement and disposal.

Centralized Grease Systems

Lubrication Systems Company offers centralized grease systems that are designed to ensure equipment reliability while making the work environment safer for maintenance personnel. Our grease systems remove the requirement to access remote grease points, especially in confined spaces, when equipment is in operation and ensures continuous application of small, uniform amounts of grease to critical lubrication points.

Lubrication Systems Company offers centralized grease systems that are designed to ensure equipment reliability while making the work environment safer for maintenance personnel. Our grease systems remove the requirement to access remote grease points, especially in confined spaces, when equipment is in operation and ensures continuous application of small, uniform amounts of grease to critical lubrication points.

Centralized systems are best practice to ensure proper application of grease and to reduce the risks associated with improper maintenance (ex. under / over greasing or human error, such as adding incorrect or contaminated grease). Centralized systems can also help avoid damage to seals and elevated bearing temperatures.

Types of Systems

- Dual Line lubrication systems

- Single Line lubrication systems

- Parallel and Progressive system arrangements

Benefits of Centralized Grease Systems

- Significant savings from reduced lubricant consumption

- Better utilization of direct manual labor

- Reduced bearing failures

- Less time required for lubricant changeout and inspection

- Less programmed maintenance required

As systems typically include long lines, precise metering valves, injectors, fittings, pumps, controllers and additional connections that can malfunction due to vibration, air entrainment and other environmental impacts it is important that systems are monitored and maintained on a constant basis.

RelaDyne Reliability Services provides a full suite of equipment services for centralized grease systems, including design, installation, commissioning, maintenance, and repair.

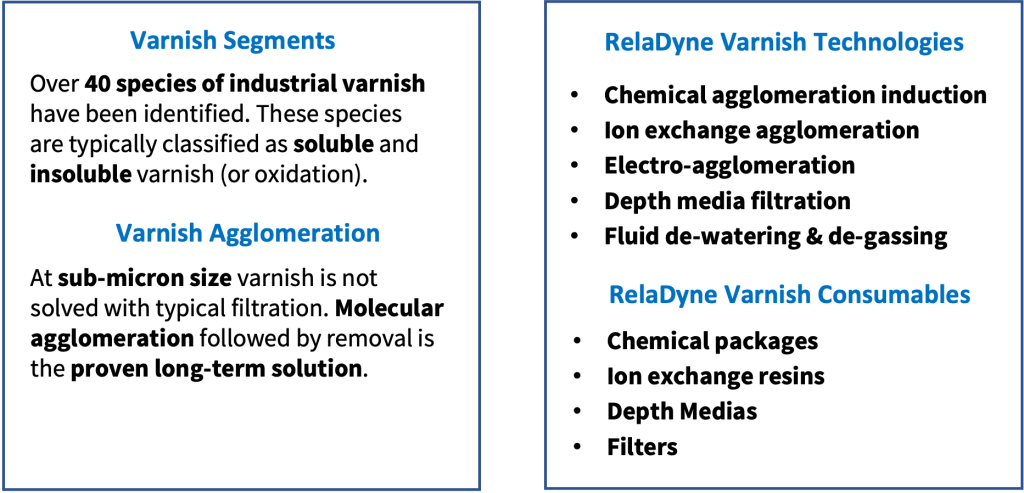

Varnish Mitigation Equipment

Lubrication Systems Company combined with RelaDyne Reliability Services offers varnish mitigation equipment to extend the life of your hydraulic and lubrication fluids.

RelaDyne has proven through years of expertise and our patented process to be a global leader in varnish remediation and prevention. From ‘sticky’ elevators to injection molding systems to hydro-power turbines, RelaDyne can eliminate your varnish challenges.

While RelaDyne’s turn-key varnish mitigation services remediate current varnish problems, and our equipment ensures you don’t have repeat problems.

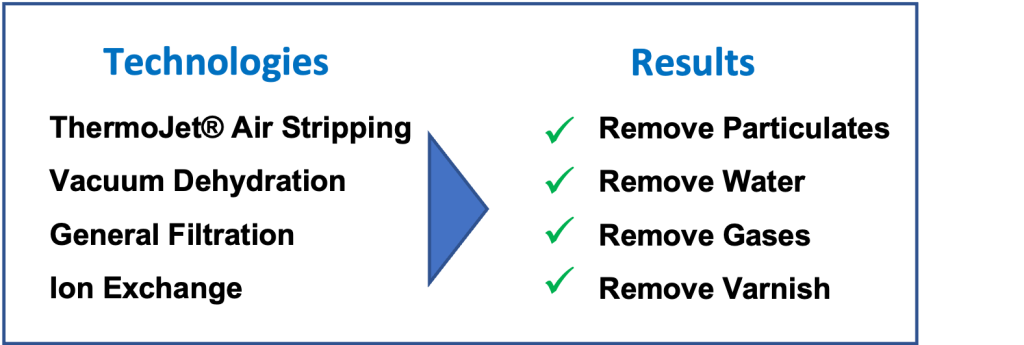

Full Compliment of Technologies and Products

Providing complete customer peace-of-mind, RelaDyne experts are available to test and evaluate your fluids to ensure proper varnish mitigation equipment selection and application.

Our autonomously operating technologies are applied independently or in packages to treat 100% of your varnish challenges and return your fluid to OEM specified TAN values.

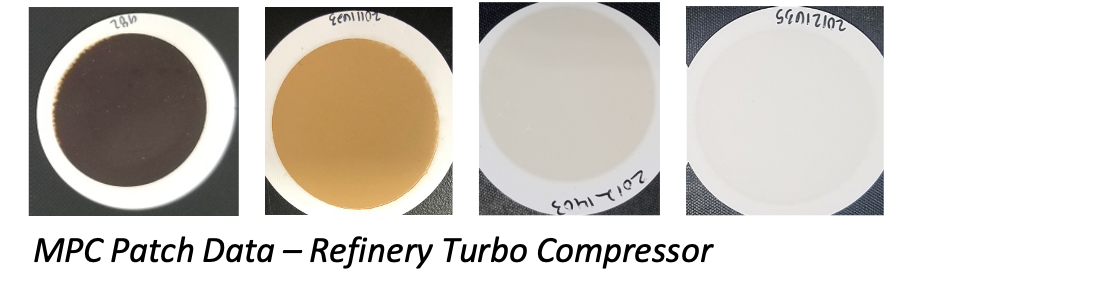

Sample Products

Typical Results

Pump & Compressor Systems

RelaDyne Reliability Services, through wholly-owned SICELUB® and partners SES International® and Rosscor® have brought the best of Dutch pump and compressor systems to the Americas.

From well-head, two-screw multiphase pump packages to commercial refrigeration compressor packages we provided the expertise and process reliability you require.

Our expertise stretches beyond the equipment to turn-key installation, commissioning, start-up, 24/7 operations, maintenance, and repair.

-

Refrigeration Solutions

-

Multiphase Pumps Solutions

-

Pump Solutions

-

Compressor Solutions

-

Chiller Solutions

Refrigeration Solutions

Customizable commercial refrigeration packages typical in general industry and food & beverage processes and supply chains:

Howden Compressors (approved packager for over 50 years)

300 to 1,000 m3/hr (175 – 600 cfm)

High efficiency 4-stage oil separation system

PLC control system to client specifications

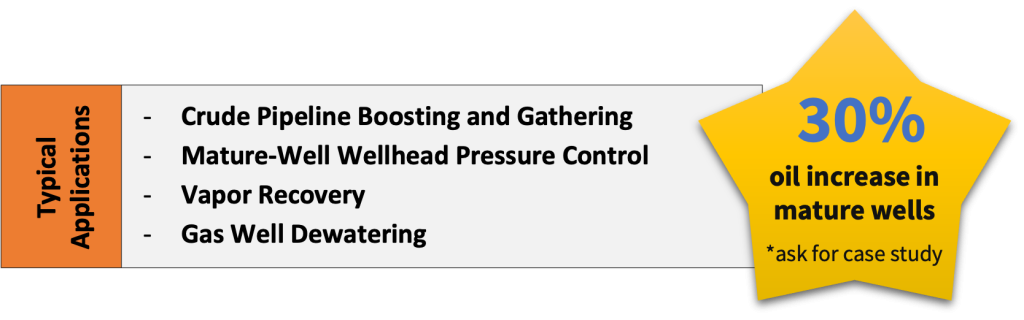

Multiphase Pump Solutions

Multiphase pump packages and systems typical in oil & gas upstream and midstream applications.

Houttuin twin-screw pump OEM – Holland factory

API 676 compliance

Up to 100% gas volume fraction (GVF)

Remote & local system controls

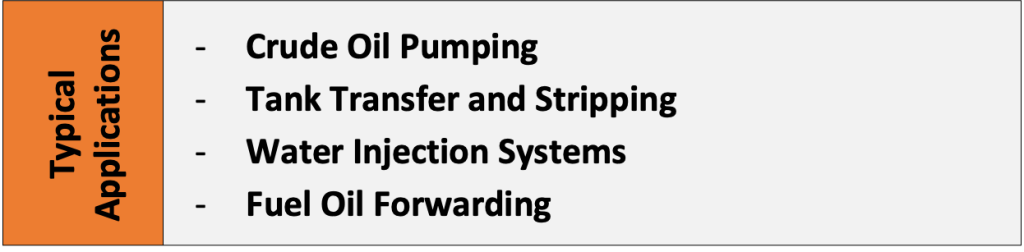

Pump Solutions

Wide range of pump solutions typically centered around centrifugal, single, or two and three screw pumps.

Typical pumps include: Houttuin, Allweiler, IMO, Warren, Torishima

Full range of capacities and pressures

Compliance with industry standards: API, ISO, VDMA, HI, etc.

From simple pump/motor/baseplate to fully automated systems

Compressor Solutions

Multiphase pump packages typical in oil and gas upstream and midstream applications.

Howden Compressors (approved packager for over 50 years)

1,000 to 24,000 m3/hr (600 – 14,000 cfm)

High efficiency 4-stage oil separation system

PLC control system to client specifications

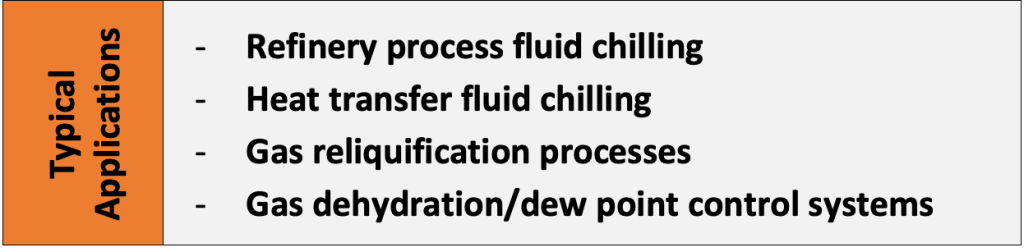

Chiller Solutions

Wide range of industrial fluid chilling solutions commonly found in industrial processing, chemical, petrochemical and oil & gas industries.

Howden Compressors (approved packager for over 50 years)

1,000 to 24,000 m3/hr (600 – 14,000 cfm)

High efficiency 4-stage oil separation system

PLC control system to client specifications