Oil & Hydraulic Fluid Purification and Reconditioning

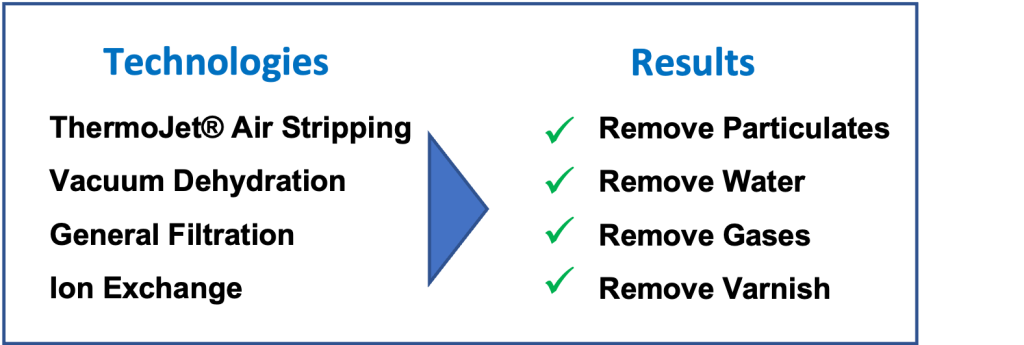

Ensure equipment reliability and eliminate expensive fluid disposal or replacement with RelaDyne Reliability Services’ comprehensive suite of Purification and Reconditioning equipment.

Contact us for equipment parts, upgrades, accessories, and on-site equipment services. Services include installation, inspection, start-up, commissioning, maintenance, repair, and refurbishment. All parts and services adhere to OEM specification and standards.

This equipment is available for: Purchase, Rental, On-site services

ThermoJet® Oil Purifiers

ThermoJet® delivers industry leading oil dehydration and degasification through Lubrication Systems Company’s patented air-stripping technology. With over 30 years of global industrial expertise ThermoJet® is your trusted, safe, “set-and-forget” solution.

- Removes free, emulsified & dissolved water. Reach levels below 50 ppm!

- Safely remove gases including H2S, ethane, chlorine, and propane

- Discharge to ambient, flare, or a scrubber

- Doesn’t require operational support

- Kidney loop can be in lube oil system or embedded in compressor / turbine lube oil reservoir

- Combine with various media or varnish filtration options (Ion Exchange, Depth Media, SelectSorb, Fuller’s Earth, etc.) to create a full-service system

The ThermoJet® air stripping process combines nitrogen or ambient air stripping with pump-free vacuum principles to safely, quickly and consistently purify oil. This unit sets the industry benchmark for delivering peace-of-mind through years of hassle-free, operator-free functionality.

THERMOJET Oil Purifier

Vacuum Dehydration Units (VDUs)

RelaDyne Reliability Services offers best-in-class Vacuum Dehydrators based on years of design and operational experience.

- Remove free, emulsified & dissolved water

- Safely remove gasses including H2S, ethane, chlorine, and propane

- Discharge to ambient, flare or a scrubber

- Kidney loop in lube oil systems

- Combine with various media or varnish filtration options to create a full-service system

- Self-contained and skid-mounted for increased mobility and ease-of-use

- PLC controller for simple operations

Water and gas contamination can cause extreme damage to bearings and hydraulics as well as become a safety concern when hydrocarbons are saturated in the oil. Up to 75% of mechanical failure can be attributed to particulate or water contamination in oil. Preventing contaminants from getting in the oil allows the oil to operate effectively and increases the overall reliability of your equipment.

General Filtration

The constant in proper lubrication management is product cleanliness. RelaDyne Reliability Services provides the products you need to support filtration from lubricant reception to initial equipment fill to lubricant replacement and disposal.